We typical start with an MDF which is a central point for all network communications. Usually this is simply your server room or main network closet. The acronym MDF stands for main distribution frame, the nomenclature originated with telephony setups from the mid-20th century.

The term MDF is typically only used if you have an IDF, intermediate distribution frame. An IDF is a smaller rack or network closet to distribute connections in a warehouse or floors of a building. You can have many IDFs, but only one MDF.

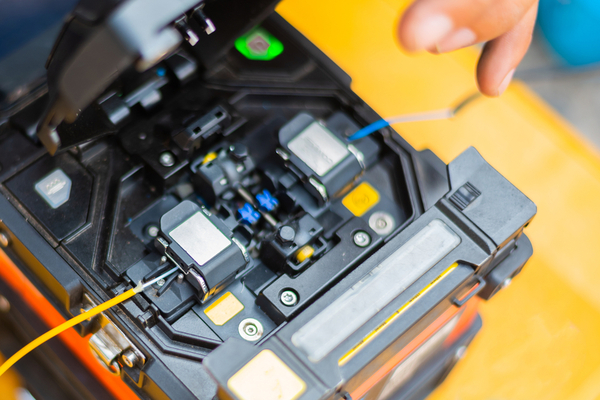

We run high speed fiber optic cable between the MDF and IDFs, and this allow for our clients to future proof their network installations. By running OM3 type cabling or greater, the client has a wide range of bandwidth they can utilize from 1GB to 40GB. This allows the business to run their current requirements, but also able to upgrade the networking equipment without changing their fundamental infrastructure. IDFs are also utilized for any devices 300 ft+ away from the MDF due to limitations with ethernet over copper wiring such as CAT6.

There are multiple strands in the OM3 fiber runs. This saves time and effort to run a single cable but provide options for supplying multiple network switches and additional IDFs.

The MDF will have a large LIU, Lightguide Interconnect Units, connected to smaller LIUs in the IDF.

Getting thick on acronyms. Contact us with any questions

This helps organize and protect the fiber optics, and allows for breakout points to other IDFs.

Once the MDF and IDFs are built, we focus on running network lines or drops to the PCs, Access Points, TVs, Projectors, etc. It is critical the cabling be color coded and organized not only for ascetics but also for safety. There are codes enforced by Shelby County and state government that dictate exactly how the cable should be hung and the type of cable to be used with certain types of ceilings. This is when you hear the terms plenum and riser wiring. Be aware plenum is always more expensive due to the manufacturing and safety requirements.

J-hooks are used to bundle and hang the cabling through ceilings, floors and walls. The hooks are critical for any job, but are rarely seen by clients.

On new installations there is typically electrical conduit ran from the top of the wall down to a box. This is where the cable is terminated and a network jack is installed. The jacks are specific to the cabling type such as cat5e, cat6, cat6A. The jacks snap into a plate and the plate is screwed down on to the box. It’s critical that the jack be of high quality such as Panduit.

We then test and certify the cable from the jack back to the patch panel in the MDF or IDF. Our cable installers have this process down to a science, and we can quickly isolate and resolve any issue related to the overall process described. We complete the run or drop with a high quality patch cable.

Please give us a call if you are interested getting an estimate on your job.